- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

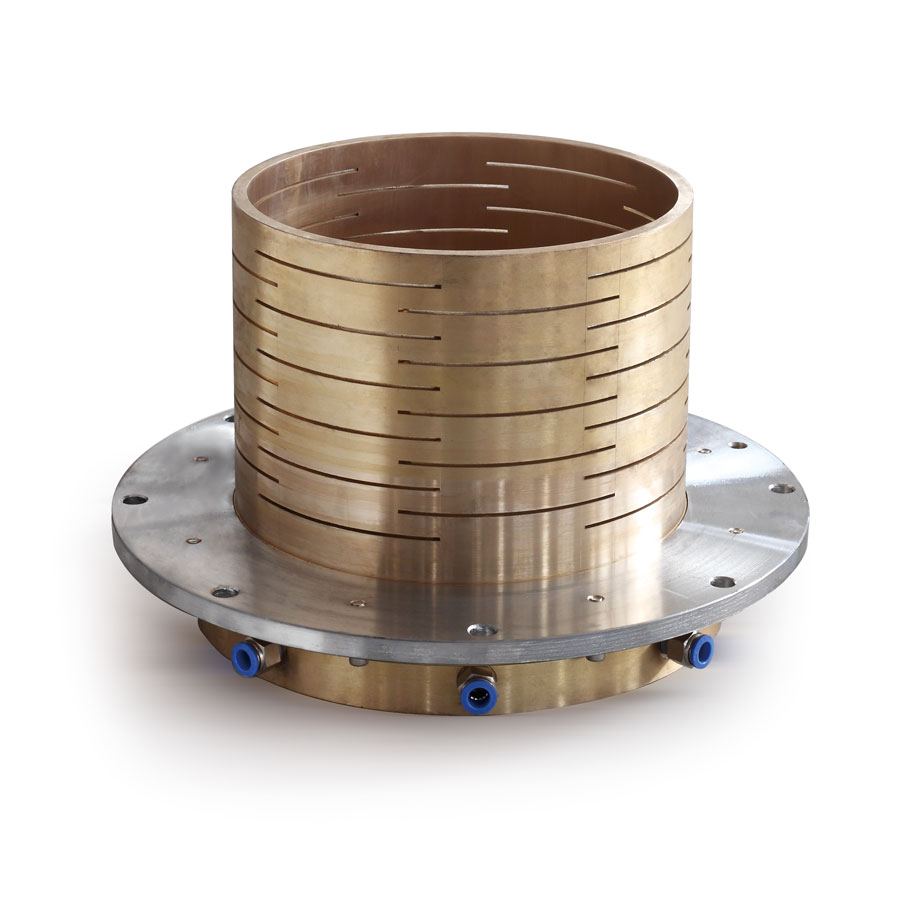

Customized Calibration Sleeve advantage

2025-01-25

A customized calibration sleeve offers several advantages, particularly in processes like pipe, tube, or profile extrusion. Below are the key benefits of using a tailored calibration sleeve:

1. Improved Product Quality

Precise Dimensions: A customized calibration sleeve ensures that the extruded product meets exact dimensional tolerances.

Consistent Wall Thickness: It helps maintain uniform wall thickness across the product, which is crucial for structural integrity and performance.

Surface Finish: Custom sleeves can be designed to enhance the surface finish, reducing the need for post-processing.

2. Enhanced Process Efficiency

Faster Calibration: Tailored sleeves are optimized for the specific material and product geometry, reducing the time required for cooling and calibration.

Reduced Scrap Rates: By ensuring precise calibration, customized sleeves minimize errors, leading to lower material waste.

Shorter Setup Time: A perfect fit for the extruded product eliminates the trial-and-error adjustment phase.

3. Material Compatibility

Specific Material Needs: Custom sleeves can be designed for various materials (e.g., PVC, HDPE, or PEX), considering their unique cooling and shaping characteristics.

Special Coatings: Options like PTFE or chrome plating on the sleeve can enhance performance by reducing friction or wear.

4. Process Versatility

Support for Complex Profiles: Customized sleeves can accommodate unique shapes or profiles that standard calibration sleeves cannot handle.

Multi-Product Support: Design modifications allow a single sleeve to calibrate multiple products with slight dimensional variations.

5. Extended Equipment Life

Reduced Wear and Tear: A well-matched sleeve reduces stress on the extruder and downstream equipment, prolonging their lifespan.

Optimized Cooling: Efficient heat transfer in customized sleeves prevents overheating or warping, protecting both the sleeve and the extruded product.

6. Cost-Effectiveness

Lower Operational Costs: Faster calibration and reduced waste lead to significant cost savings over time.

Tailored Investment: While the initial cost may be higher, the long-term benefits of customization outweigh the expense through improved efficiency and reduced downtime.

7. Application-Specific Features

Special Design Elements: For applications requiring specific mechanical properties or tolerances (e.g., medical tubing, automotive profiles), the sleeve can be tailored to ensure compliance with industry standards.

Integration with Cooling Systems: Customized sleeves can be designed to integrate seamlessly with water or air cooling systems, enhancing heat dissipation.

8. Competitive Advantage

Unique Product Offerings: Customization enables manufacturers to produce unique or specialized products that differentiate them in the market.

Improved Lead Times: Faster and more efficient production cycles enable quicker delivery to customers.

Conclusion

A customized calibration sleeve aligns with the specific needs of your extrusion process, maximizing precision, efficiency, and quality. While it involves upfront investment, the long-term advantages in performance and cost savings make it a valuable asset in high-precision manufacturing.