- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

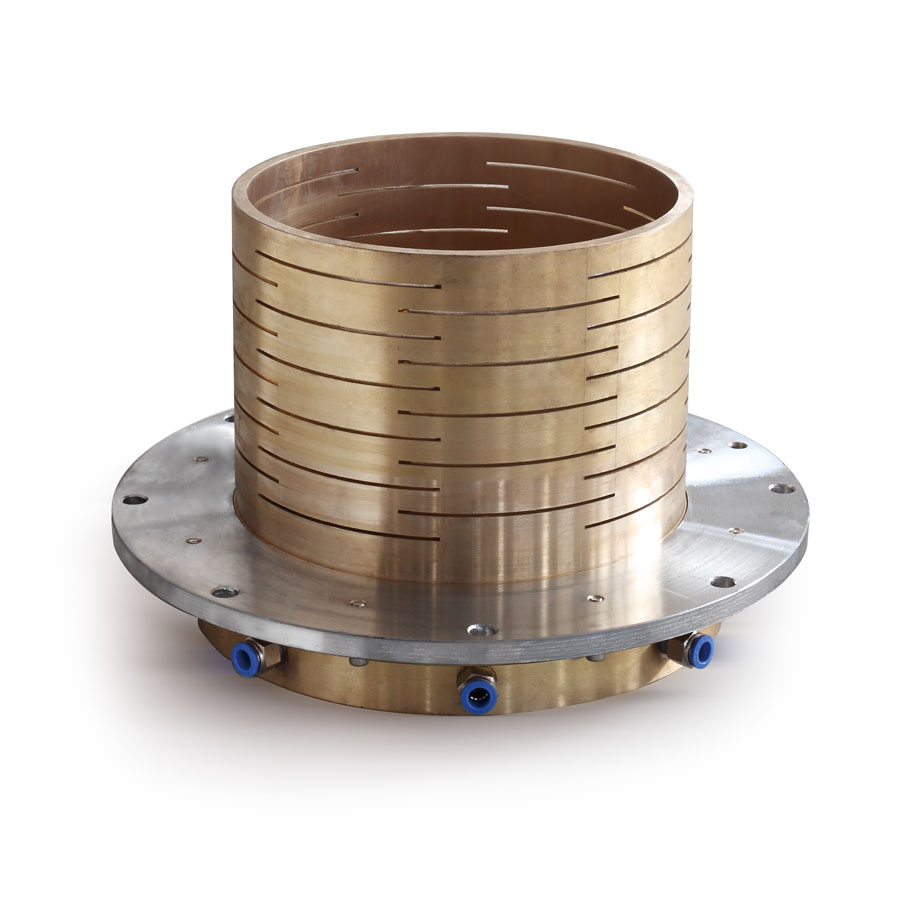

what area perferred use Durable Calibration Sleeve

2025-02-20

Preferred Areas for Using Durable Calibration Sleeves

A Durable Calibration Sleeve is an essential component in the extrusion process, particularly for pipe and profile production. It ensures that the extruded material maintains precise dimensions and smooth surface quality as it cools and solidifies. The areas where it is most preferred include:

1. High-Precision Pipe & Tube Manufacturing

Water and Gas Pipes → Ensures exact outer diameter and uniform wall thickness.

Electrical Conduits → Required for smooth inner surfaces to facilitate wire pulling.

Medical Tubing → Used for producing precision tubing in the medical industry.

2. Construction & Infrastructure

PVC & HDPE Pipes → Used in underground drainage, sewage, and water transport systems.

Profiles for Windows, Doors, and Facades → Ensures accuracy in size and shape for proper fitting.

3. Automotive & Aerospace Industries

Plastic Fuel Lines and Fluid Transfer Tubes → Requires high durability and dimensional accuracy to avoid leaks.

Protective Cable Sheathing → Provides smooth finishes and controlled dimensions.

4. Industrial and Chemical Processing

Corrosion-Resistant Pipes → Used in industries handling chemicals, oils, or aggressive fluids.

Heat-Resistant Ducting → Essential for controlled airflow and insulation.

5. Wire and Cable Insulation

Telecommunications & Power Cables → Ensures smooth outer surfaces and exact diameters to meet industry standards.

6. Food and Beverage Industry

FDA-Approved Tubing → Used for food-grade pipes where cleanliness and hygiene are critical.

Why Choose Durable Calibration Sleeves?

✅ Longer Service Life – Resistant to wear and tear from high-volume production.

✅ Better Cooling Efficiency – Aids in faster solidification for increased productivity.

✅ Consistent Product Quality – Ensures precision, reducing material waste.