- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How did Bulk Calibration Sleeve work ?

2025-03-27

Great — here’s a breakdown of how a Bulk Calibration Sleeve typically works, especially in the context of oil and gas or well completions (which is where the term most often comes up):

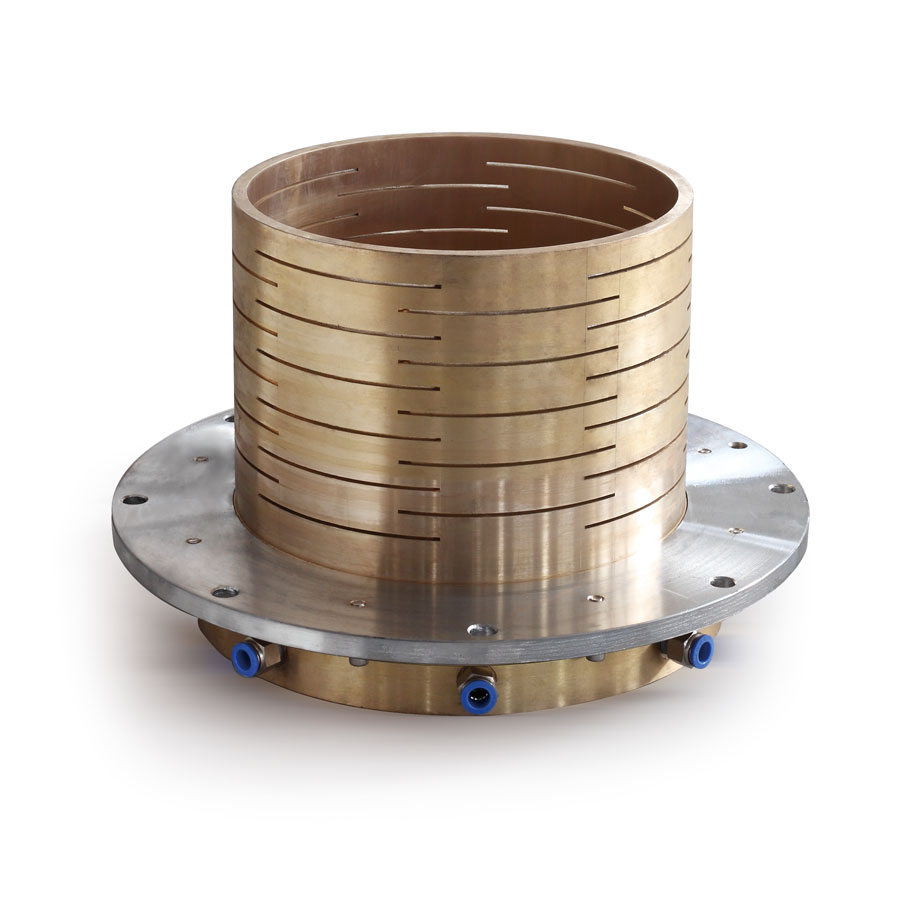

What is a Bulk Calibration Sleeve?

A Bulk Calibration Sleeve is a mechanical tool used in the completion phase of a well, often in hydraulic fracturing (fracking). It's used to simulate or calibrate the response of other sleeves or downhole tools, especially fracturing sleeves or ports, before the actual treatment or stimulation begins.

How It Works:

1. Installation

The sleeve is installed in the casing or tubing string along with other completion equipment.

It’s positioned in the wellbore like a regular stage sleeve or port.

2. Calibration Run

Before starting the actual fracturing operation, a ball or dart is dropped from the surface.

This ball lands on a seat inside the Bulk Calibration Sleeve, creating a seal.

3. Pressure Build-Up

Surface pumps apply pressure.

Because the ball has sealed the sleeve, pressure builds up in the casing.

4. Pressure Test / Calibration

This pressure is monitored to calibrate the surface pumping equipment, or to verify the pressure integrity of the system.

It can also simulate how the system will behave when actual fracturing sleeves are opened later.

5. No Opening Mechanism

Unlike actual frac sleeves that open ports to the formation, bulk calibration sleeves do NOT open or initiate communication with the formation. They are used purely for testing.

6. Bypass

After calibration, pumping is stopped.

The sleeve may be bypassed, or the ball is pushed through using pressure or mechanical action to continue operations.

✅ Key Benefits:

· Ensures pressure integrity of the wellbore system before high-pressure treatments.

· Allows calibration of surface equipment without risking premature sleeve activation.

· Helps detect leaks or problems early in the process.