- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

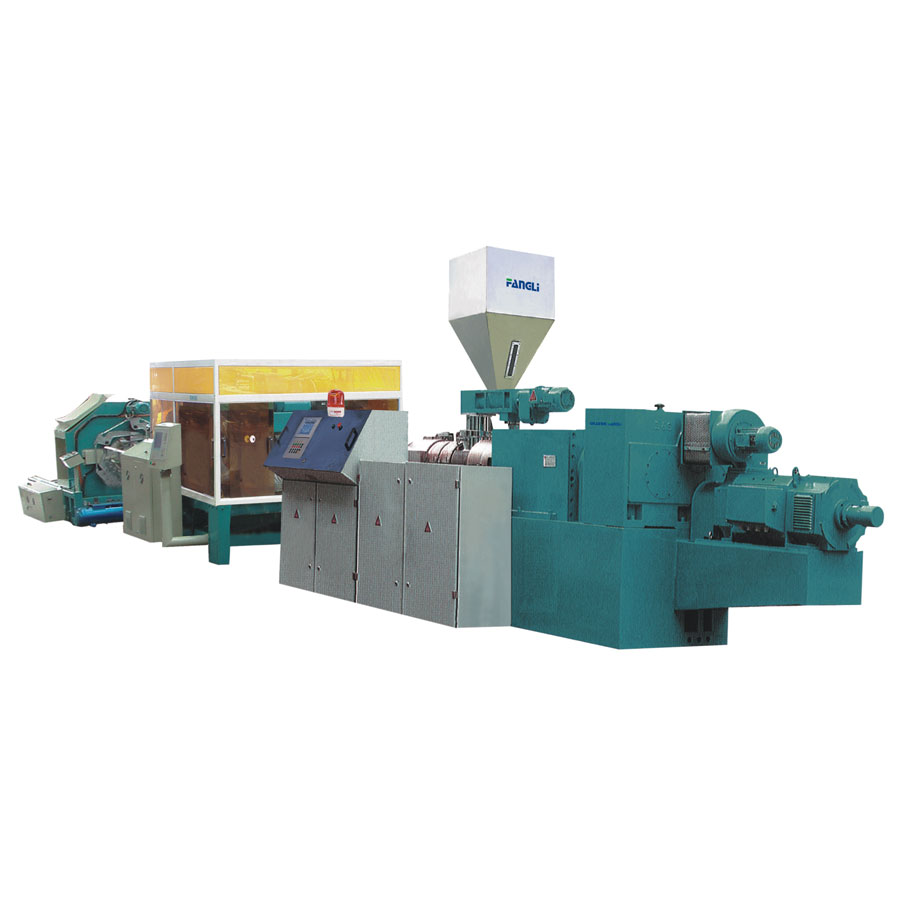

Type of Material about corrugated pipe extruder UL

2025-04-14

A corrugated pipe extruder that is UL certified can handle various types of plastics, each suited for different applications. Here's a breakdown of the common materials used in corrugated pipe extrusion:

1. Polyethylene (PE):

High-Density Polyethylene (HDPE): Widely used due to its durability, flexibility, and resistance to chemicals and impact. It's suitable for drainage pipes, water management systems, and cable protection.

Low-Density Polyethylene (LDPE): Less rigid and generally used for less demanding applications compared to HDPE.

2. Polypropylene (PP):

Known for its stiffness and heat resistance, making it ideal for hot water pipes and in applications requiring high thermal stability.

3. Polyvinyl Chloride (PVC):

Has good tensile strength and is highly resistant to chemicals and corrosive environments. PVC is commonly used for underground wiring and sewer lines.

4. Polyamide (Nylon):

Offers excellent resistance to wear and abrasion, often used in high-performance applications, though less common for corrugated pipes.

The choice of material depends on the application requirements, such as chemical resistance, flexibility, durability, and thermal properties. Each material also affects the design of the extruder, particularly the screw design, die design, and cooling system, to ensure optimal processing and quality of the corrugated pipes.