- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What environment use Durable Calibration Sleeve?

2025-04-18

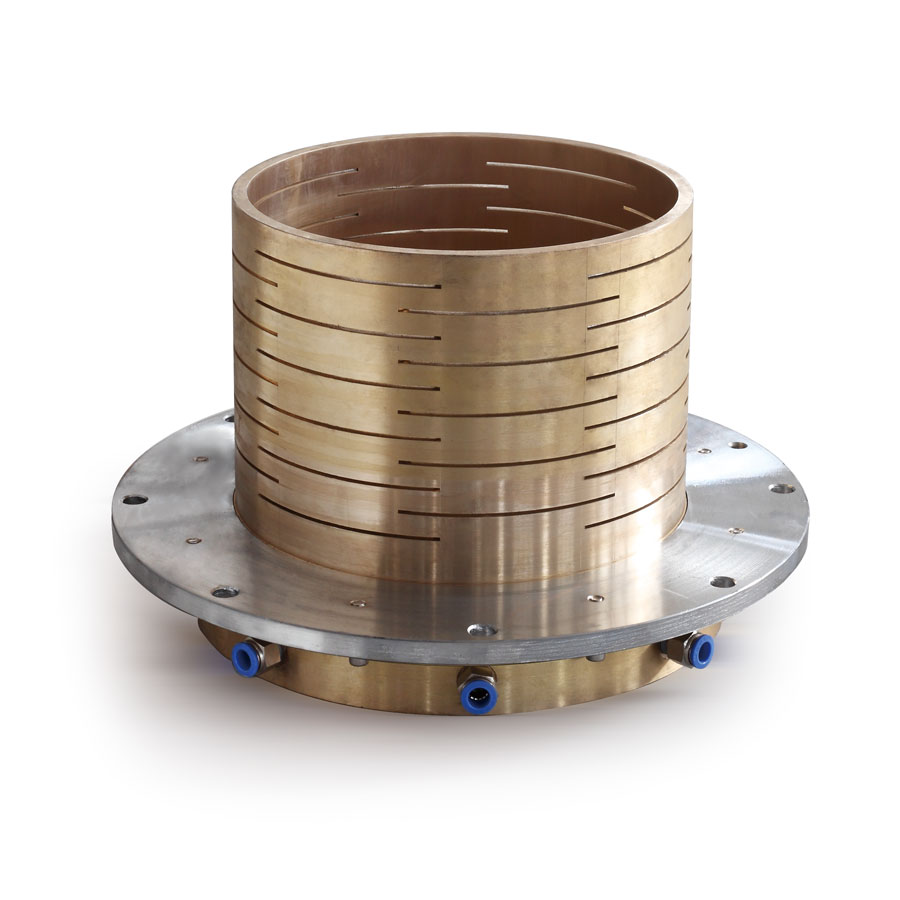

Durable Calibration Sleeves are used in plastic pipe extrusion environments, especially where precision, efficiency, and long-term wear resistance are critical. These sleeves help shape and cool the pipe immediately after it exits the die-head, ensuring consistent diameter, roundness, and smooth surface finish.

✅ Common Environments Where Durable Calibration Sleeves Are Used:

1. High-Speed Pipe Extrusion Lines

For PE, PP, PVC, CPVC, or HDPE pipes

Especially in double-wall corrugated, smooth-wall pressure, or large-diameter structured-wall pipe production

Durable sleeves withstand intense vacuum pressure and cooling demands

➡️ Why used? To handle constant friction and thermal shock during high-speed production.

2. Large Diameter Pipe Production

Pipes ranging from 160 mm up to 2000 mm or more

Often used for sewage, drainage, or industrial conduits

➡️ Why used? Stronger calibration sleeves are required to maintain roundness under weight and vacuum stress.

3. Underground Electrical Conduit Pipe Lines (UL Compliant)

For producing UL 651 certified corrugated conduit

Durable sleeves help ensure tight tolerances and smooth interior walls to meet electrical code specs.

➡️ Why used? To maintain UL-required wall thickness and diameter accuracy.

4. Multi-Layer or Foam-Core Pipe Production

Where layer bonding precision and diameter control are critical

Examples: three-layer sewage pipes (inner recycled, middle foam, outer virgin)

➡️ Why used? Durable calibration sleeves offer stable forming, even with fluctuating melt flow.

5. Abrasive or High-Filler Material Applications

For pipes containing calcium carbonate, glass fiber, or recycled material

These can wear out standard sleeves quickly

➡️ Why used? Durable sleeves (often made of chrome-plated steel or wear-resistant alloys) last longer under abrasive contact.

6. Cleanroom or Medical-Grade Pipe Extrusion

For lab, medical, or ultra-pure water systems

Often uses smooth small-diameter PVC or PP-R pipes

➡️ Why used? Precision and smooth surface are essential; durable sleeves help eliminate micro-defects.

Summary Table:

Environment Why Use Durable Calibration Sleeve

High-speed pipe extrusion lines Withstand friction, maintain shape at fast cooling rates

Large-diameter pipe production Maintain roundness and structural integrity

UL electrical conduit manufacturing Ensure strict diameter tolerance and surface quality

Multi-layer / foam-core pipe lines Provide stable shaping during complex material layering

Abrasive/recycled material processing Resist wear and maintain lifespan

Cleanroom or precision pipe production Deliver flawless surface and dimension accuracy