- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What is a corrugated pipe extruder UL

2025-06-24

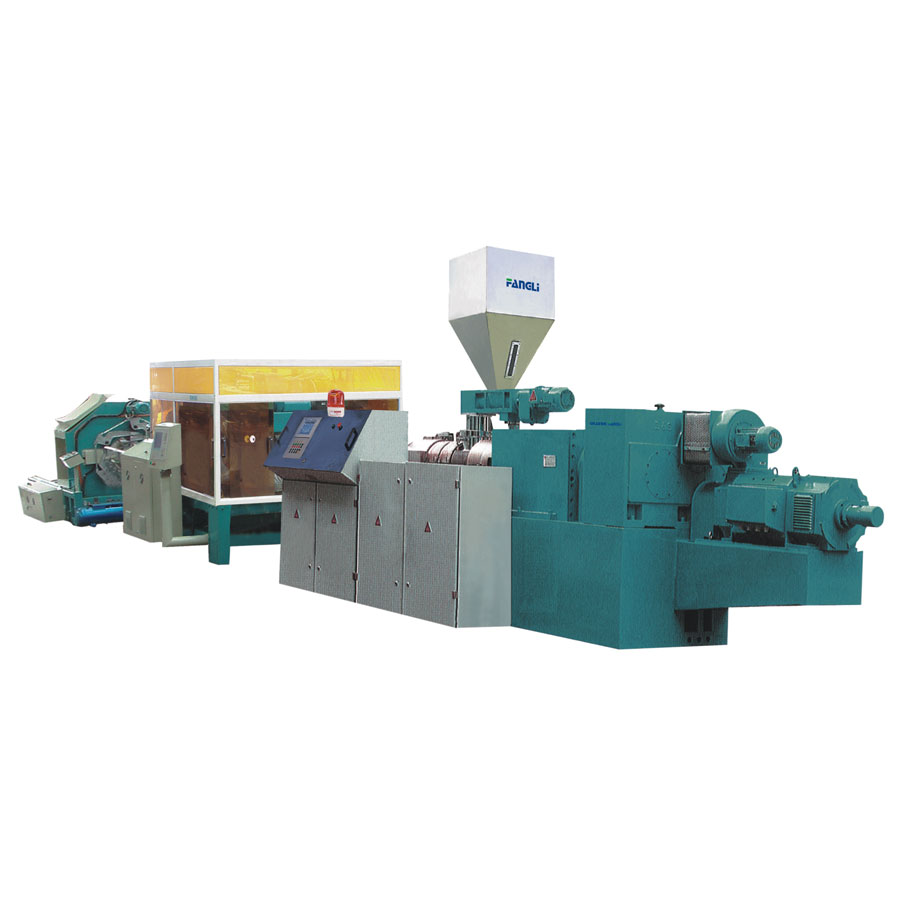

A "corrugated pipe extruder UL" refers to a corrugated plastic pipe extrusion line that meets UL (Underwriters Laboratories) certification standards. These systems are typically used to produce electrical conduit or drainage pipes with a corrugated structure, and UL certification ensures they meet U.S. safety and performance standards.

What Is a Corrugated Pipe Extruder?

A corrugated pipe extruder is a specialized plastic extrusion line that produces corrugated (i.e., ridged or wavy) pipes, often used in:

Electrical conduit (UL651, UL1653, etc.)

Drainage systems

HVAC and cable protection ducts

Sewer and stormwater pipes

Materials often include PVC, HDPE, PP, or PE-RT.

✅ Why Choose a UL-Certified Corrugated Pipe Extruder?

UL certification is critical for manufacturers aiming to sell or install piping in regulated environments, especially in North America.

Key benefits:

|

Feature |

Benefit |

|

UL Safety Standard Compliance |

Ensures pipes meet electrical/fire safety codes (esp. UL651, UL1653 for conduit). |

|

Regulatory Acceptance |

Required for electrical installations in the U.S./Canada. |

|

High Production Precision |

UL standards require tight tolerances—machines are built accordingly. |

|

Enhanced Quality Control |

Includes die design, cooling, vacuum calibration, and corrugator precision. |

|

Market Access |

Easier to work with contractors and government projects requiring UL-listed piping. |

Common Components of a UL-Certified Corrugated Pipe Extrusion Line:

1. Single or Twin Screw Extruder

Material-specific (e.g., PVC → twin screw; PE → single screw)

2. Corrugator

Forms the pipe shape using metal mold blocks – UL lines use high-speed, water- or air-cooled corrugators for better shaping.

3. Mold Blocks & Forming System

UL requires precise mold tooling to ensure uniform wall thickness and corrugation pitch.

4. Vacuum & Cooling System

Maintains dimensional stability and rapid cooling for UL dimensional tolerances.

5. Cutting & Haul-Off Unit

Servo-controlled for precision in length and cut – essential for UL labeling.

6. Online Monitoring System (Optional)

Some UL-compliant lines include diameter and wall thickness measurement systems.

UL Standards Commonly Applied:

|

UL Code |

Description |

|

UL651 |

Standard for Schedule 40/80 PVC Conduit |

|

UL1653 |

Standard for HDPE Conduit (for communication cables, etc.) |

|

UL2024B |

For plenum-rated HDPE innerduct |

|

UL94 |

Flammability standard for plastic materials |

✅ Who Needs This?

Conduit Manufacturers targeting U.S. markets

OEMs or Contractors needing UL-compliant pipe supply

Exporters to North America