- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

News

Customized Extrusion Line of PVC-UH Pipe use environment

A customized extrusion line for PVC-UH (Unplasticized High-Performance Polyvinyl Chloride) pipe involves creating a system specifically designed to manufacture PVC-UH pipes with specific properties suited to their intended environment. The use environment of PVC-UH pipes can influence the design and......

Read MoreWhat are the advantages of PP-R pipe extrusion production line

The advantages of PP-R pipe extrusion production line mainly include: High production efficiency: It can produce large quantities of pipes quickly and stably to meet market demand. Energy saving and environmental protection: Compared with other pipes, the production process of PP-R has lower energ......

Read MoreEmbracing German Design Innovating CPVC Pipe Extrusion

German CPVC Line Applications The German-designed CPVC pipe extrusion line is well-suited for producing pipes used in plumbing and construction. This durable extrusion equipment can extrude CPVC compound into high-quality piping for water supply, drainage, and other building applications. Key Feat......

Read Morewhat environment need to Customized Extrusion Line for Solid Wall Pipe

Customizing an extrusion line for solid wall pipe manufacturing involves several factors that are specific to the pipe's material, size, and desired production characteristics. The environment and setup needed for such a customized extrusion line include the following: 1. Material-Specific Enviro......

Read MoreIndividual Equipment of Solid Wall Pipe Extrusion Line use area

In a solid wall pipe extrusion line, each piece of equipment plays a specific role in the overall process. Here’s a breakdown of the individual equipment used in such a line and their respective areas of use: 1. Raw Material Handling System Use Area: Feeding and storage of polymer materials. ......

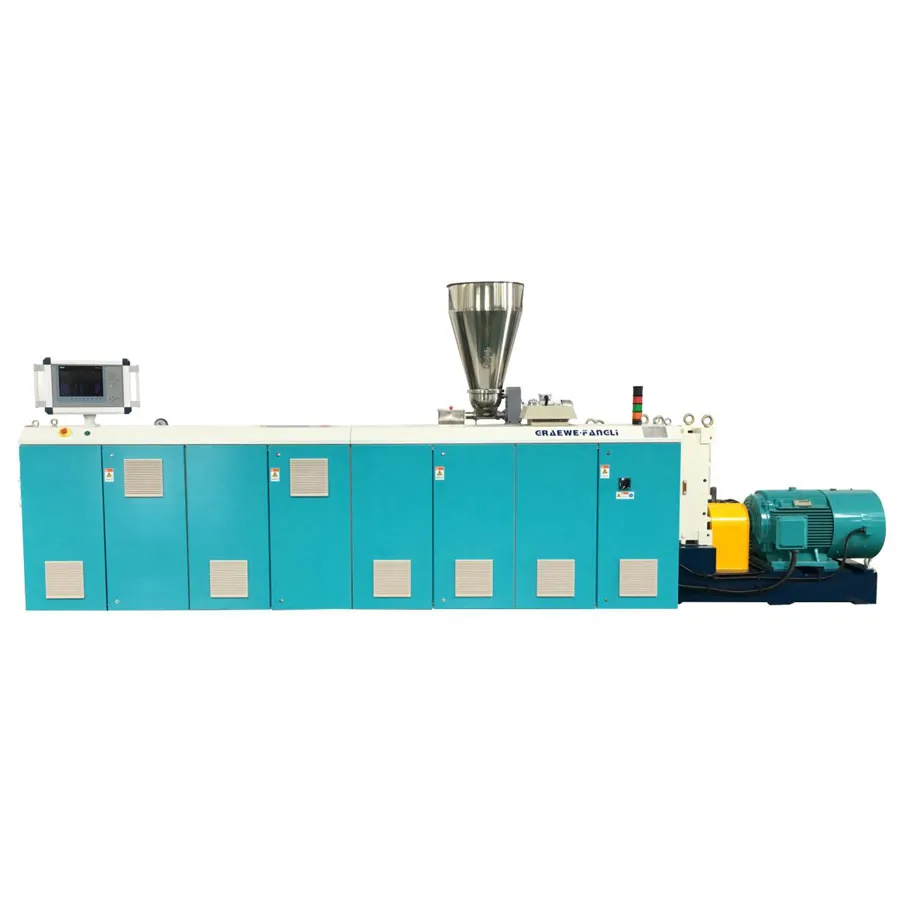

Read MoreHow to adjust the screw gap of conical type twin-screw plastic extruder

Adjusting the screw gap of a conical type twin-screw plastic extruder usually includes the following steps: Safety preparation: Make sure the equipment is shut down and let it cool down to avoid high temperature damage. Remove the protective cover: Remove the protective cover of the screw so that ......

Read More