- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Industry Knowledge

How to improve the production efficiency of PEPP double-wall corrugated pipe extrusion equipment

Improving the production efficiency of PEPP double-wall corrugated pipe extrusion equipment involves optimization in many aspects, including equipment commissioning, process improvement and material management. Here are some effective ways to improve production efficiency: 1. Optimize equipment set......

Read MoreWhy Customized Extrusion Line of PVC-UH Pipe

Customizing an extrusion line for PVC-UH (unplasticized high-performance polyvinyl chloride) pipes is essential for several reasons, particularly when it comes to meeting specific production needs, ensuring quality, and optimizing efficiency. Here’s why a customized extrusion line is often necessary......

Read MoreHow to use German Design pipe extrusion line

Using a German Design pipe extrusion line involves several key steps, including preparation, setup, operation, and maintenance. Below is a general guide on how to use a pipe extrusion line, which should be applicable to most German-designed systems. However, always refer to the specific manufacturer......

Read MoreWhat is advantage of CPVC Pipe Special Complete Set Extrusion Line

The CPVC (Chlorinated Polyvinyl Chloride) Pipe Special Complete Set Extrusion Line is designed specifically for producing CPVC pipes, which are commonly used for hot and cold water distribution, industrial liquid handling, and chemical transport. This specialized extrusion line offers several advant......

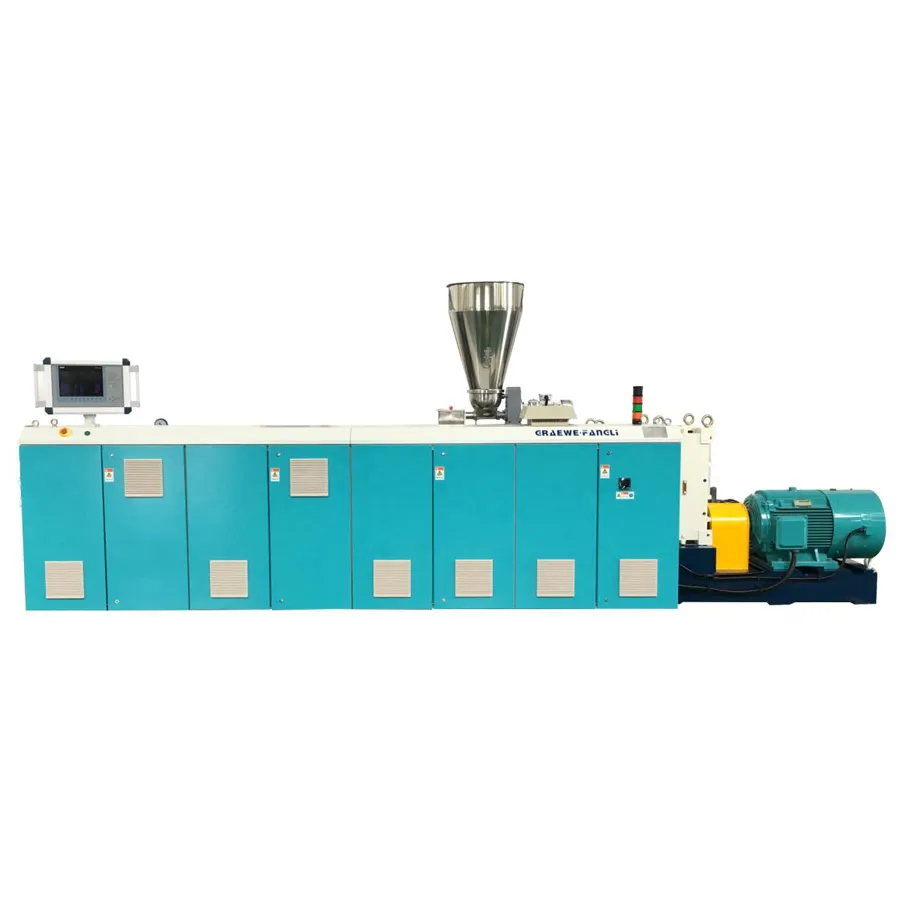

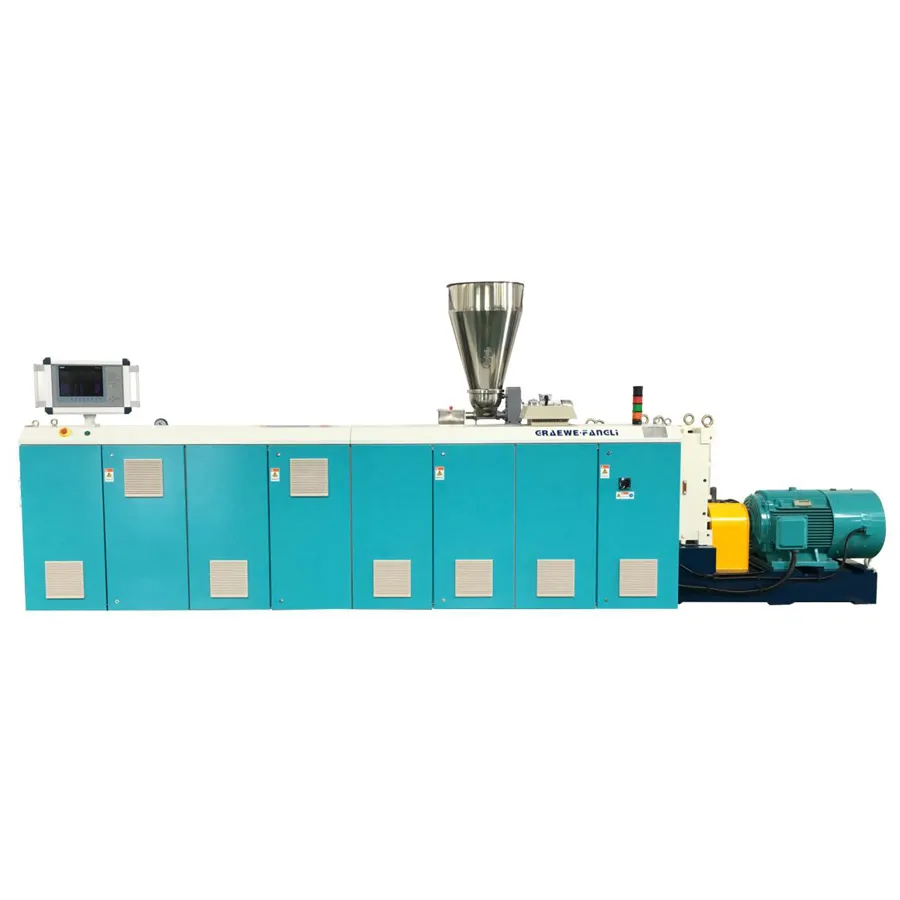

Read MorePrinciple of counter-rotating parallel type twin-screw extruder

The working principle of counter-rotating parallel type twin-screw extruder involves the rotation of two parallel screws in opposite directions. Here are its main principles: Screw design: In a counter-rotating parallel type twin-screw extruder, two parallel screws rotate in opposite directions. Ea......

Read MoreWhat are the advantages of conical type twin-screw plastic extruder

Conical type twin-screw plastic extruders have many significant advantages in the field of plastic processing, including the following aspects: 1. High mixing efficiency The two screws of the conical twin-screw extruder rotate alternately with each other to achieve efficient mixing and uniform dis......

Read More