- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

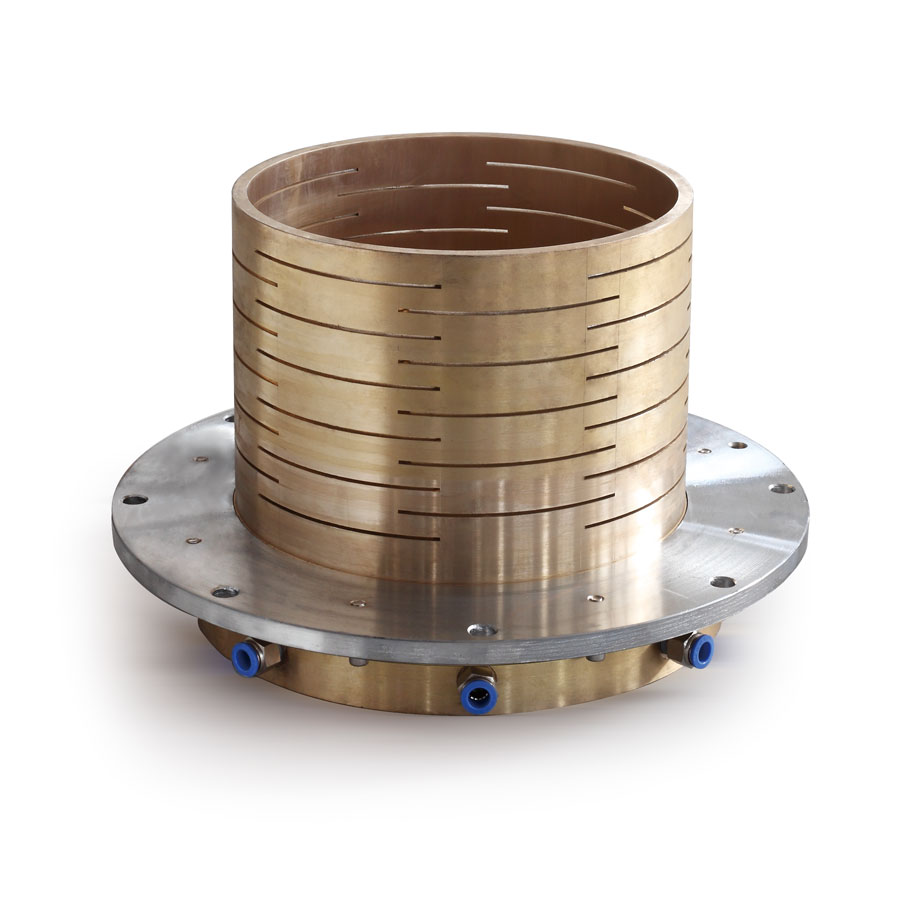

Durable Calibration Sleeve

2025-01-17

A calibration sleeve is a crucial component in plastic pipe extrusion, responsible for shaping and cooling extruded pipes to precise dimensions. Durability in calibration sleeves is essential to maintain consistent pipe quality, reduce downtime, and enhance overall production efficiency.

Key Features of Durable Calibration Sleeves:

Material Composition: High-quality calibration sleeves are typically made from metals with excellent thermal conductivity and wear resistance. For instance, tin bronze (ZQSn 6-6-3) is commonly used due to its durability and effective cooling properties.

Ningbo Fangli Technology Co., Ltd.

Adjustability: Some advanced calibration sleeves offer adjustable diameters, allowing for real-time modifications during production without halting the process. This feature enhances flexibility and reduces downtime.

GundG Extrusionstechnik

Cooling Efficiency: Effective cooling mechanisms, such as intensive water cooling facilities, are integrated into durable calibration sleeves to ensure rapid and uniform cooling of the extruded pipe, maintaining dimensional accuracy.

Nilkanth Plastic Machine

Surface Finish: High-quality sleeves often feature chrome plating or smooth inner designs to reduce friction, prevent pipe surface defects, and extend the sleeve's lifespan.

Nilkanth Plastic Machine

Benefits of Using Durable Calibration Sleeves:

Enhanced Pipe Quality: Maintains precise pipe dimensions and surface finish, ensuring high-quality end products.

Increased Production Efficiency: Reduces the need for frequent replacements and adjustments, leading to uninterrupted production runs.

Cost Savings: Minimizes maintenance and replacement costs due to extended sleeve lifespan and reduced downtime.

Considerations When Selecting a Calibration Sleeve:

Compatibility: Ensure the sleeve is suitable for the specific pipe materials (e.g., PE, PP, PVC) and diameters used in your production line.

Manufacturer Reputation: Opt for products from reputable manufacturers with a proven track record of quality and durability.

Customization: Some manufacturers offer tailored solutions to meet specific production requirements, which can be beneficial for specialized applications.

Notable Manufacturers:

Here are some manufacturers known for producing durable calibration sleeves:

CCA (via RS9 Consulting)

CCA develops high-performance calibration sleeves for plastic pipe extrusion, focusing on reliability and efficiency. Their products are used globally to optimize complex production processes.

RS9 Consulting

G&G Extrusionstechnik GmbH

Specializes in adjustable calibration sleeves that allow for diameter adjustments during production, enhancing flexibility and reducing downtime.

GundG Extrusionstechnik

Ningbo Fangli Technology Co., Ltd.

Offers calibration sleeves made of tin bronze, known for their wear resistance and excellent thermal conductivity, suitable for various pipe extrusion applications.

Ningbo Fangli Technology Co., Ltd.

Nilkanth Engitech Private Limited

Provides gun metal fabricated calibration sleeves with intensive cooling facilities and adjustable water rings, ensuring stability and durability in pipe production.

Nilkanth Plastic Machine

SCITEQ

Offers adjustable calibrating sleeves designed to optimize plastic pipe production, allowing easy control of pipe diameter during the manufacturing process.

https://siamintercorp.co.th

Investing in durable calibration sleeves is vital for maintaining high-quality production standards in plastic pipe extrusion, leading to long-term operational efficiency and cost-effectiveness.