- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What's the Specifications details on a specific model of Single screw Extruder UL

2025-01-20

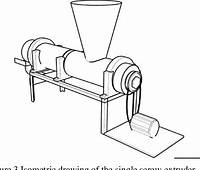

ingle-screw extruders are pivotal in the plastics industry, facilitating the melting, mixing, and shaping of polymer materials. These machines consist of a single rotating screw within a heated barrel, which conveys raw plastic materials through a die to form continuous shapes.

Key Specifications:

Screw Diameter: Typically ranges from 0.75 inches to 10 inches, with common sizes being 1.5", 2.5", 3.5", 4.5", and 6". The diameter influences the machine's throughput and the types of products it can produce.

Arlington Machinery

Length-to-Diameter Ratio (L/D): This ratio, representing the screw's length divided by its diameter, usually falls between 24:1 and 36:1. A higher L/D ratio allows for better mixing and heating of the polymer.

Arlington Machinery

Motor and Gearbox: Extruders utilize variable-speed AC or DC motors. DC motors have been standard, but AC motors are gaining popularity due to their efficiency and reliability. The gearbox reduction is crucial to maintain appropriate screw output speeds for different materials.

Arlington Machinery

Barrel Cooling: Cooling can be achieved through air or water. Air cooling, typically using fans, is simpler, while water cooling is more effective but requires additional maintenance.

Arlington Machinery

Control Systems: Modern extruders are equipped with temperature controllers for barrel zones, die, and downstream zones, RPM gauges for screw speed, amp gauges for motor load, melt temperature gauges, and pressure indicators at the die head.

Arlington Machinery

UL Certification:

Underwriters Laboratories (UL) certification ensures that equipment meets rigorous safety and performance standards. While specific models may have UL certification, it's essential to verify this with the manufacturer or supplier. UL certification can be particularly important for equipment used in regulated industries or regions where compliance with safety standards is mandatory.

Example Models:

Here are some single-screw extruder models that you might consider:

2" Welex Extruder 24:1 L/D, 20HP

This model features a 2-inch screw diameter with a 24:1 L/D ratio and a 20 HP motor, suitable for various plastic extrusion applications.

Arlington Machinery

2" Davis Standard Extruder, Model DS20, 24:1 L/D, Air Cooled

Equipped with a 2-inch screw, 24:1 L/D ratio, and air-cooled barrel, this extruder is designed for efficient processing of different polymers.

Arlington Machinery

2.0" Welex, 30:1 L/D Ratio, Vented Barrel, 25 HP AC Motor

Featuring a 2-inch screw, 30:1 L/D ratio, vented barrel, and a 25 HP AC motor, this extruder is ideal for applications requiring venting and higher throughput.

Arlington Machinery

GW Series Single Screw Extruder

Suitable for extruding materials like PP, PE, PS, PC, ABS, and PMMA, this model offers a specially designed screw and barrel for optimal performance.

GPM Machinery

Single Screw Extruder for Homogenizing Bulk Solids

Designed for mixing and homogenizing bulk solid materials, this extruder is constructed from locally available materials, emphasizing accessibility and ease of maintenance.

ResearchGate

When selecting a single-screw extruder, consider factors such as the materials to be processed, desired throughput, and specific application requirements. Consulting with manufacturers or suppliers can provide tailored information to ensure the chosen extruder meets your operational needs.