- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

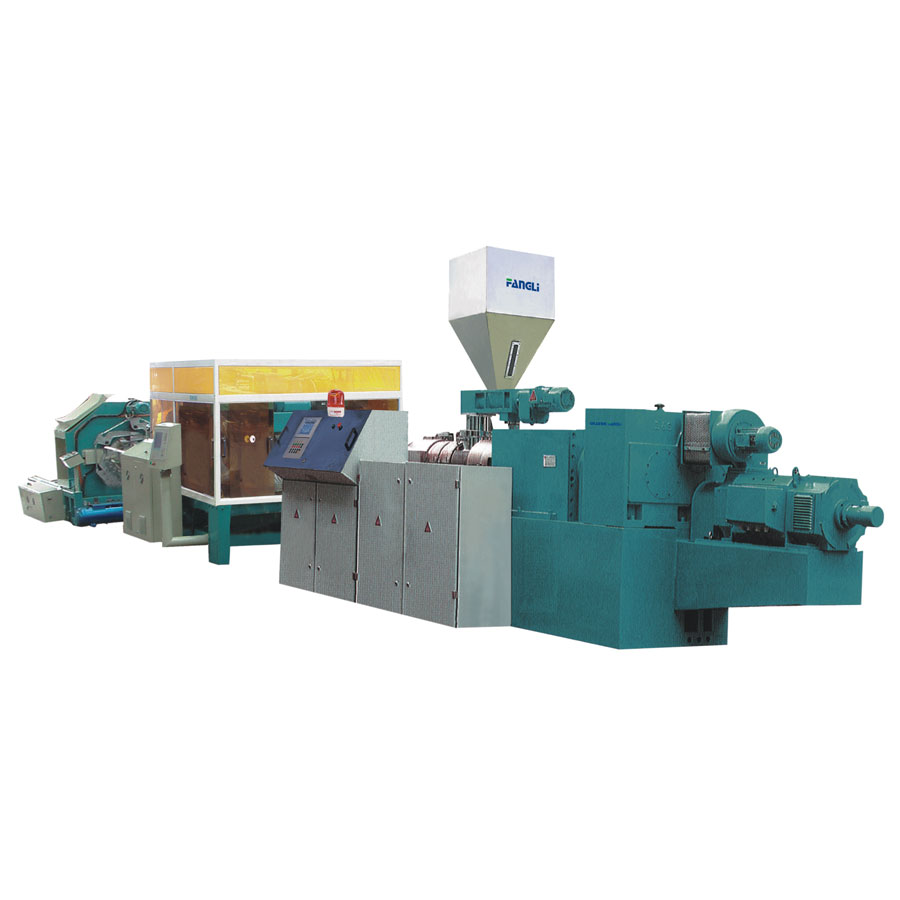

What does "UL" mean in this corrugated pipe machine

2025-04-21

In the context of a corrugated pipe machine, "UL" stands for Underwriters Laboratories, which is an independent safety certification organization based in the United States. When you see "UL" associated with a corrugated pipe machine, it usually means one of the following:

✅ 1. UL Certification for the Finished Pipes

Most commonly, "UL" refers to the pipes produced by the machine being certified — especially for electrical conduit pipes used in the U.S.

For example, UL 651 is the standard for Schedule 40 and 80 PVC Conduit and corrugated electrical conduit.

Pipes produced must meet:

Flame resistance

Impact strength

Crush resistance

Marking and dimensional tolerances

✅ 2. UL-Approved Machine Components

Sometimes, the machine itself uses UL-certified electrical or safety components, such as:

Control panels

Heaters

Temperature controllers

Emergency stop systems

Wiring and electrical enclosures

This ensures the machine is safe to operate and meets North American electrical safety codes.

✅ 3. UL as a Marketing/Export Requirement

For export to the U.S. market, especially for electrical piping systems, buyers often require that the:

Machine can produce UL-compliant products

Production process supports UL compliance

⚠️ Important Clarification:

The machine itself is usually not UL-certified as a whole system — instead, it is designed to produce UL-compliant pipes and uses UL-listed components.

✅ Summary:

"UL" in Corrugated Pipe Machine What It Means

UL-labeled pipes Pipes meet UL 651 or similar standard

UL components Machine parts follow UL safety rules

Market suitability Enables export of UL-approved pipes to the U.S.

Let me know if you’d like a sample UL 651 test checklist, or pipe extrusion line diagram for UL pipe production.