- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

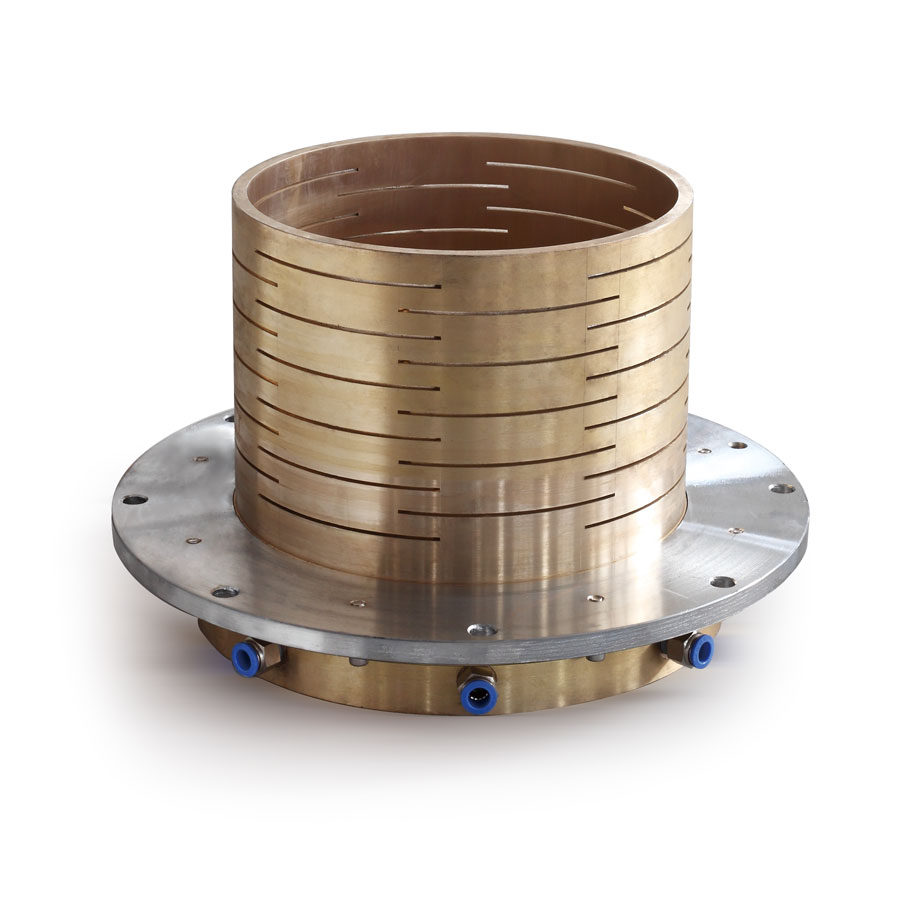

What is the Advanced Calibration Sleeve

2025-04-22

An Advanced Calibration Sleeve is a precision-engineered tool used in plastic pipe extrusion lines, especially for corrugated or solid-wall plastic pipes, to shape and size the extruded pipe as it cools and solidifies. It is a critical component in ensuring dimensional accuracy, smooth surface finish, and high-speed production stability.

Key Functions of an Advanced Calibration Sleeve:

1. Pipe Shaping: It helps the molten plastic take the final desired diameter and roundness after it exits the die-head.

2. Vacuum Cooling Support: Often integrated with vacuum ports or channels to provide suction, which pulls the pipe tightly against the sleeve’s surface for better shape definition.

3. Heat Transfer & Cooling: Usually made of materials (e.g. chrome-plated steel or aluminum alloy) with high thermal conductivity to assist in quick cooling.

4. Surface Finish: Ensures that the outer surface of the pipe is smooth and defect-free.

5. Enhanced Durability: Advanced versions are wear-resistant, and may be coated or hardened for longer lifespan in high-speed lines.

Advanced Features Compared to Standard Sleeves:

Feature Standard Sleeve Advanced Calibration Sleeve

Cooling efficiency Moderate High (enhanced thermal design)

Precision Basic roundness Tight tolerances, high consistency

Material durability Standard steel/aluminum Hardened or coated alloys

Compatibility Limited Supports high-speed and custom profiles

Vacuum support Optional Integrated multi-zone vacuum design

Typical Applications:

HDPE double-wall corrugated pipe production

UPVC, CPVC, or PE solid wall pipes

Structured-wall or multi-layer pipe lines

Pipes for drainage, sewage, and conduit systems