- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

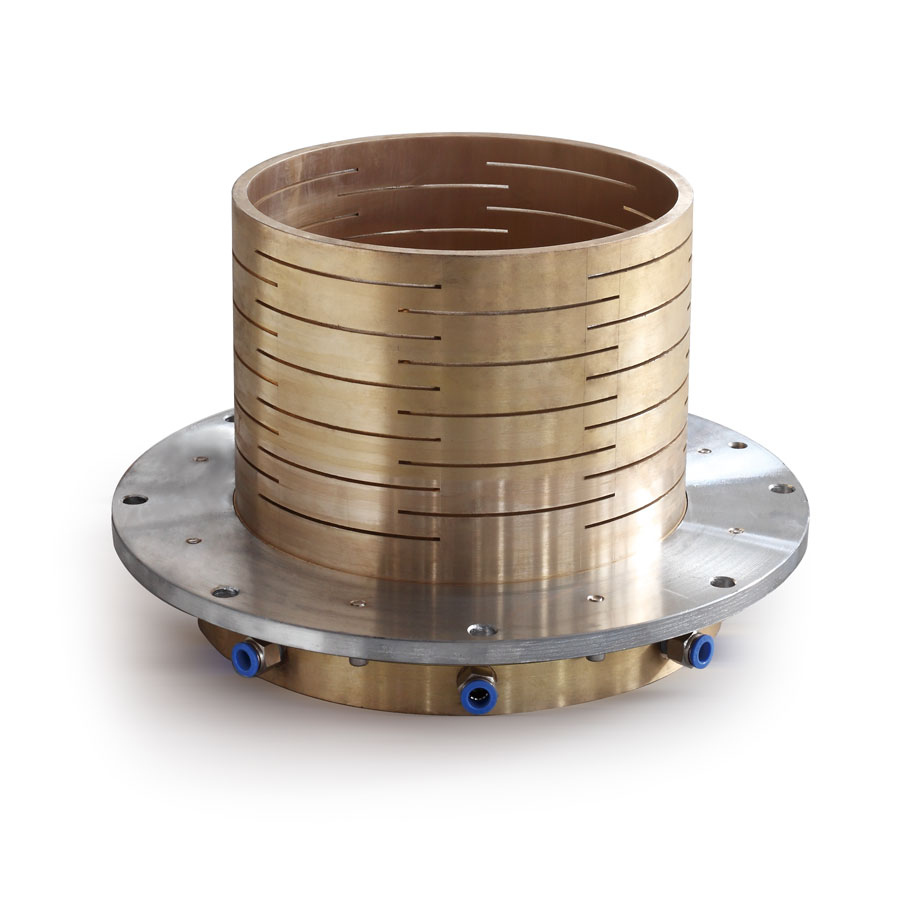

Where is the Bulk Calibration Sleeves used in?

2025-05-07

Bulk Calibration Sleeves are used in industrial plastic pipe extrusion environments where high-volume, consistent production is required. These sleeves are typically applied in large-scale manufacturing of pipes such as PVC, HDPE, PP, or PPR, especially when uniformity and dimensional accuracy are essential.

Typical Environments for Bulk Calibration Sleeves:

Environment Type Description

High-Volume Pipe Production Plants Used in facilities producing thousands of meters per day of plastic piping—e.g., water supply, drainage, telecom conduit, etc.

Vacuum Calibration Tanks Sleeves are mounted inside vacuum tanks where they help shape and stabilize the pipe using negative pressure and water

cooling.

Automated Extrusion Lines Integrated with automated lines requiring minimal downtime and consistent pipe diameter control.

Dust- and Heat-Controlled Settings Often installed in clean and temperature-stable factory zones to prevent distortion and material defects.

Corrugated or Structured Wall Pipe Lines Used when forming complex wall profiles that require robust shaping during initial cooling.

Large-Diameter Pipe Manufacturing Applied when extruding pipes with large diameters (e.g., 250mm–1000mm or more) where bulk sleeves with high structural

strength are necessary.

✅Environmental Conditions Tolerated by Bulk Calibration Sleeves:

· Temperature: Must endure contact with hot, just-extruded plastic (often >180°C).

· Water & Vacuum: Operate continuously under water spray and vacuum suction.

· Mechanical Stress: Handle friction, pipe drag, and thermal expansion cycles.

✅ Why Use a Bulk Calibration Sleeve:

· Supports mass production without frequent changeovers

· Ensures uniform diameter and roundness

· Reduces cooling time and improves throughput

· Compatible with custom pipe sizes and profiles