- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

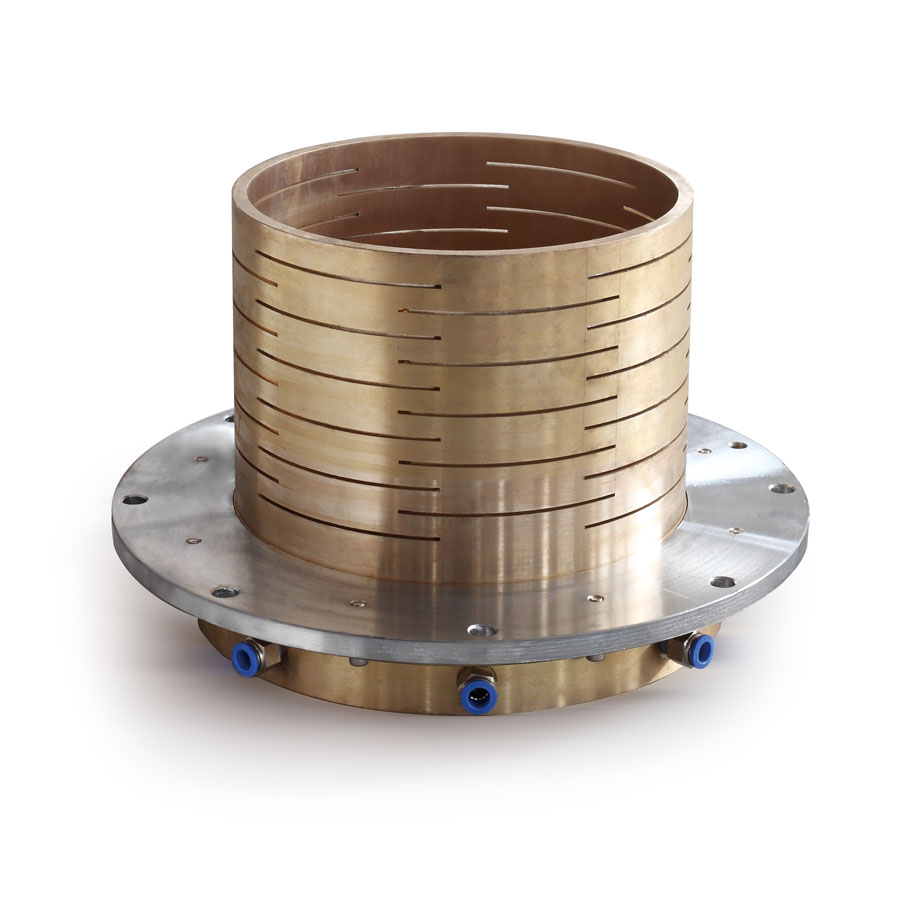

Primary Use Environments for Advanced Calibration Sleeves

2025-05-16

1. High-Speed Extrusion Lines

For HDPE, PP, PVC-U, CPVC, or structured wall pipe production.

Typical line speeds: 10–35 m/min or higher.

Demands extremely stable sizing and cooling for large diameter pipes (e.g., 110–630mm+).

2. Vacuum Tank Systems

Installed inside the vacuum calibration tanks.

Works with vacuum suction and water spray to instantly cool and shape the hot pipe after it exits the die-head.

3. Clean, Temperature-Controlled Industrial Settings

Found in automated, dust-free pipe factories.

Ensures dimensional consistency, especially where tight tolerances are required (e.g., telecom conduits or pressure-rated pipes).

4. Environments Requiring Quick Changeover

Advanced sleeves may have modular or quick-release designs, making them ideal for:

Multi-diameter production setups

Factories requiring frequent size changes

5. High-Performance Pipe Production

Corrugated pipes, multi-layer composite pipes, and UL/CE-compliant pipe lines.

Often paired with spiral die-heads, haul-off machines, and inline thickness monitoring.

Typical Industries:

Industry Use Case

Construction Underground water, gas, or sewage pipes

Telecom Optical cable protection pipes

Agriculture Irrigation or drainage pipe extrusion

Industrial Chemical-resistant or pressure pipes

Municipal Double-wall corrugated or structured wall pipe systems