- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

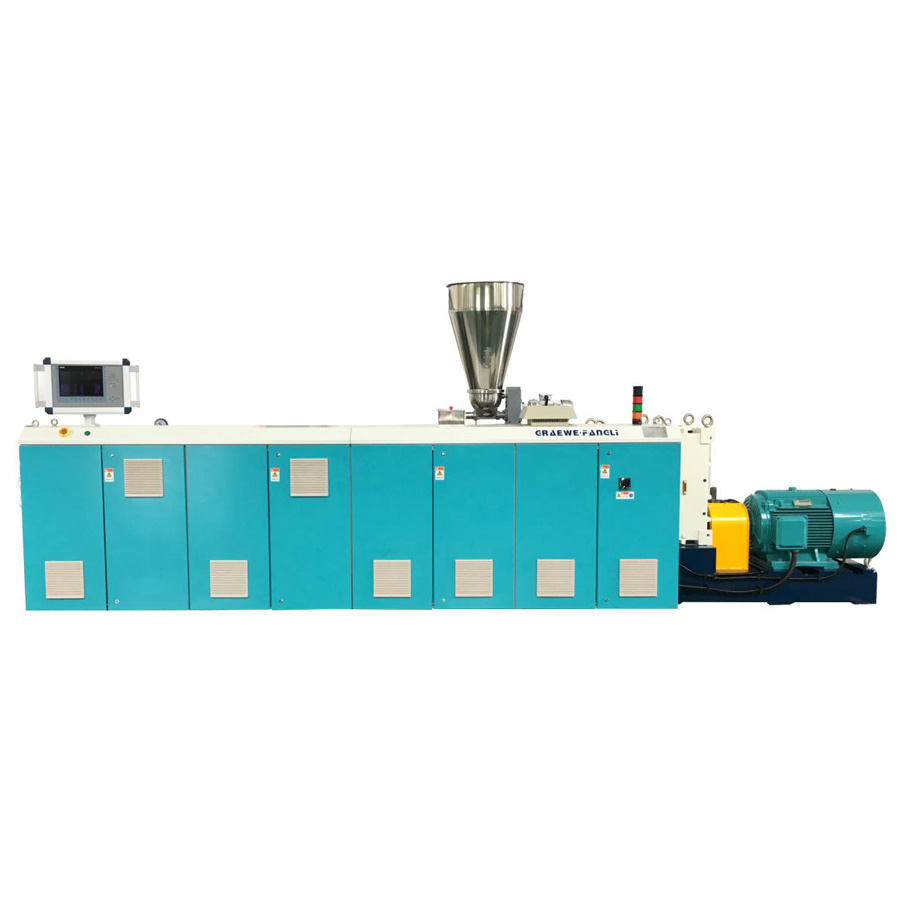

Working principle of counter-rotating parallel twin screw extruder

2025-06-05

The counter-rotating parallel twin-screw extruder is a highly efficient plastic processing equipment, mainly used for the mixing, extrusion, plasticization and other processes of plastics. It consists of two parallel screws that rotate in opposite directions. Its working principle mainly includes the following aspects:

1. The structure and rotation direction of the twin screws:

In the counter-rotating parallel twin-screw extruder, the two screws are installed in parallel and they rotate in opposite directions, that is, one screw rotates clockwise and the other screw rotates counterclockwise.

The gap between the screws is fixed, which can ensure the movement path and mixing effect of the material between the screws.

2. Feeding and transmission of materials:

The material enters the extruder from the feed port, and as the two screws rotate, the material will be pushed between the screws. Since the screws rotate in opposite directions, the material will undergo multiple processes such as shearing, friction, and compression between the screws.

This two-way rotation method allows the material to move not only in the axial direction, but also to shear, stir and squeeze in the lateral direction, promoting the uniform mixing of the material.

3. Plasticization and mixing of materials:

Under the rotation of the screw, the material is continuously heated and sheared, thereby gradually plasticizing. The structure of the screw is usually designed with different sections, such as the propulsion section, the compression section and the exhaust section. The design of different sections helps to plasticize, mix and remove gas from the material.

The material undergoes complex flow and shearing between the screws, which promotes the uniform mixing between the plastic molecular segments and ensures the homogeneity of the product.

4. Discharge of materials:

After proper heating, plasticization and mixing, the material is discharged at the front end of the extruder. The design of the extruder head determines the shape and size of the final product, and is usually used to manufacture pipes, sheets, films, granules, etc.

Due to the counter-rotation of the twin screws, the material is subjected to higher shear force and pressure throughout the process, so higher processing efficiency and better product quality can be obtained.

5. Transmission and synchronization of the screw:

In order to ensure that the two screws can accurately rotate synchronously in opposite directions, a precision gearbox or synchronization device is usually used. These devices ensure that the speeds of the screws are equal and that they can transmit sufficient torque to cope with different load requirements.

Summary: The working principle of the counter-rotating parallel twin-screw extruder is to achieve material conveying, plasticizing and mixing through the rotation of two screws in opposite directions. The different sections of the screw design enable the material to complete the expected processing process in multiple stages. Its efficient mixing and plasticizing capabilities make it widely used in plastic processing, especially in the fields of high-demand synthesis, compounding, additive mixing, etc.