- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What's the advantage of Durable Calibration Sleeve ?

2025-06-06

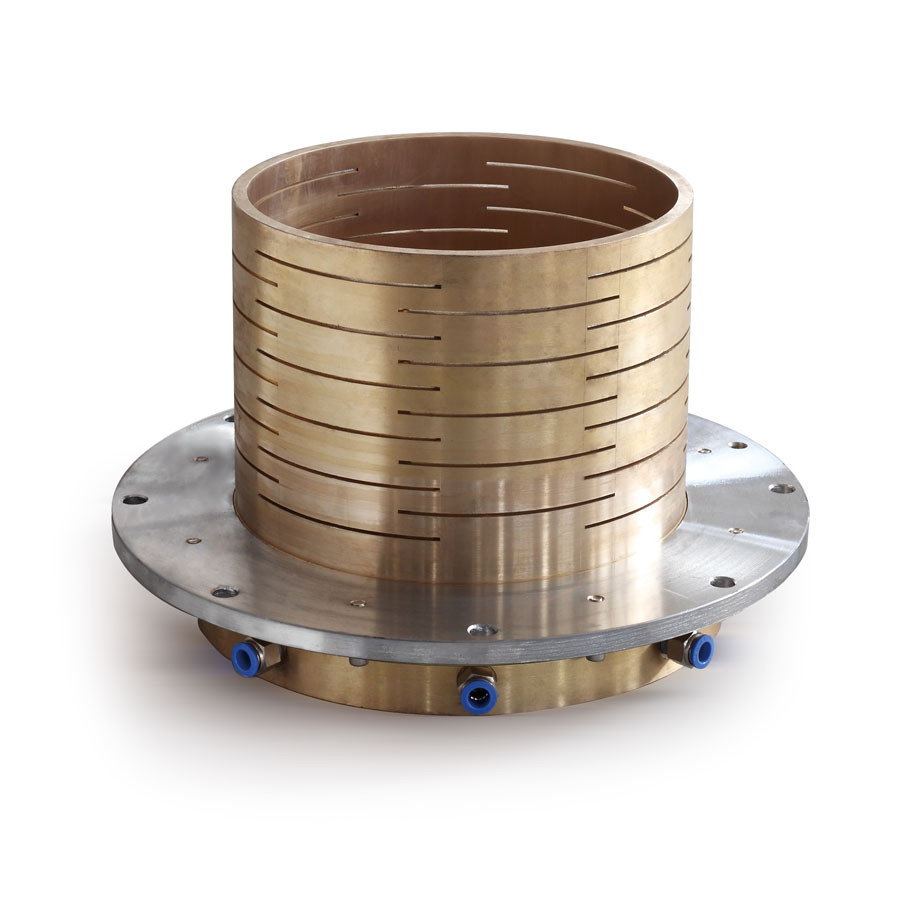

A Durable Calibration Sleeve is a key component in plastic pipe extrusion, especially during vacuum calibration. Its main job is to shape and cool the pipe accurately as it exits the die. A durable calibration sleeve adds significant value in terms of performance, cost-efficiency, and consistency.

✅ Advantages of a Durable Calibration Sleeve

1. Longer Service Life

Made from hardened stainless steel, chrome-plated alloys, or wear-resistant composites.

Resists:

Abrasive wear from rough plastics (like mineral-filled PE or recycled HDPE)

Corrosion from additives or high-humidity environments

✅ Result: Fewer replacements, lower long-term costs.

2. Better Dimensional Accuracy

Maintains precise internal diameter over time, ensuring consistent pipe OD and wall thickness.

Especially important for pressure-rated pipes (e.g., water/gas pipes needing certification).

✅ Result: Lower rejection rate, higher quality control.

3. Faster Line Speeds

Superior cooling efficiency (often with spiral water channels or optimized contact surface) allows:

Faster pipe extrusion

Reduced calibration zone length

✅ Result: Higher productivity without compromising precision.

4. Reduced Downtime

Durable sleeves reduce:

Cracks

Scratches

Frequent replacement or adjustment

✅ Result: More uptime for the extrusion line, fewer maintenance interruptions.

5. Smooth Surface Finish

High-quality surface finish on the sleeve ensures the outer surface of the pipe is smooth and defect-free.

Critical for drainage, pressure, or optical conduit pipes where surface finish matters.

✅ Result: Enhanced pipe appearance and performance.

6. Compatibility with Multiple Materials

Suitable for:

PE / PP / PVC / CPVC

Even multi-layer or foamed-core pipes

✅ Result: Flexible use across different product lines.

Ideal Use Cases

High-speed production lines

Large-diameter pipe (>110 mm)

Multi-shift operations

Tight-tolerance applications (ISO / ASTM certified)