- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

News

What impact do different inner wall colors have on HDPE double-wall corrugated pipes?

The most common HDPE double-walled corrugated pipes on the market have mostly black inner walls. However, in practical applications, HDPE double-walled corrugated pipes with inner walls of different colors such as blue, yellow, green, and red will also be encountered.

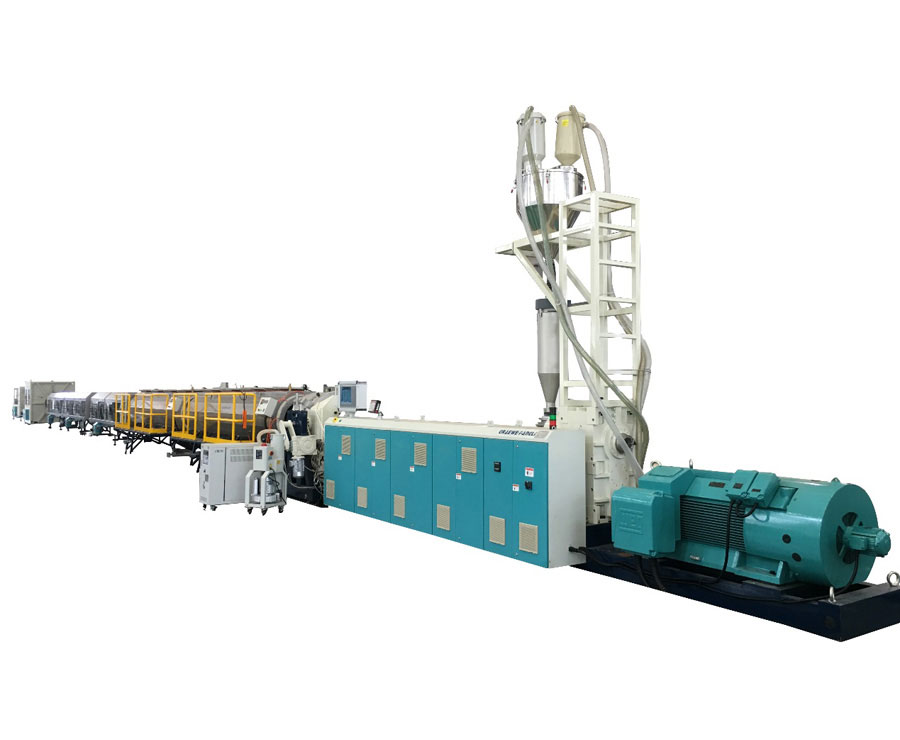

Read MoreCongratulations to Fangli PE1200U polyethylene pipe extrusion complete set of equipment for successfully completing the acceptance

Recently, Fangli Technology's ultra-thick-walled, anti-sag, low-energy PE 1200U polyethylene pipe extrusion complete set has undergone 100 hours of continuous and stable production, successfully passed various tests, successfully completed acceptance, and was put into production.

Read MoreExtrusion Line of PE Pipe process flow

Extrusion Line of PE pipe is a commonly used process for producing PE pipes. The following is the general extrusion line of PE pipe process flow: Raw material preparation: First, polyethylene (PE) particles need to be prepared as raw materials. These particles are usually screened, dried, etc. to......

Read MoreHow to choose Extrusion Line of CPVC Pipe?

When choosing an extrusion production line for CPVC pipes, you need to consider the following key factors: Production Capacity: Determine the required production capacity based on your production needs, i.e. the length or weight of CPVC pipe produced per hour or per day. This will help determ......

Read MorePipe extruder manufacturers share with you knowledge about nominal pressure/working pressure/design pressure, as well as pipeline pressure classification

Usually, when customers purchase pipelines, they will give clear pressure requirements based on the drawings. We are also accustomed to giving the price of the corresponding specifications step by step, but we have neglected to study the concept of specific pressure. Little do we know that "pressure......

Read More