- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What advantage of POK Pipe Extrusion Equipment UL

2025-06-19

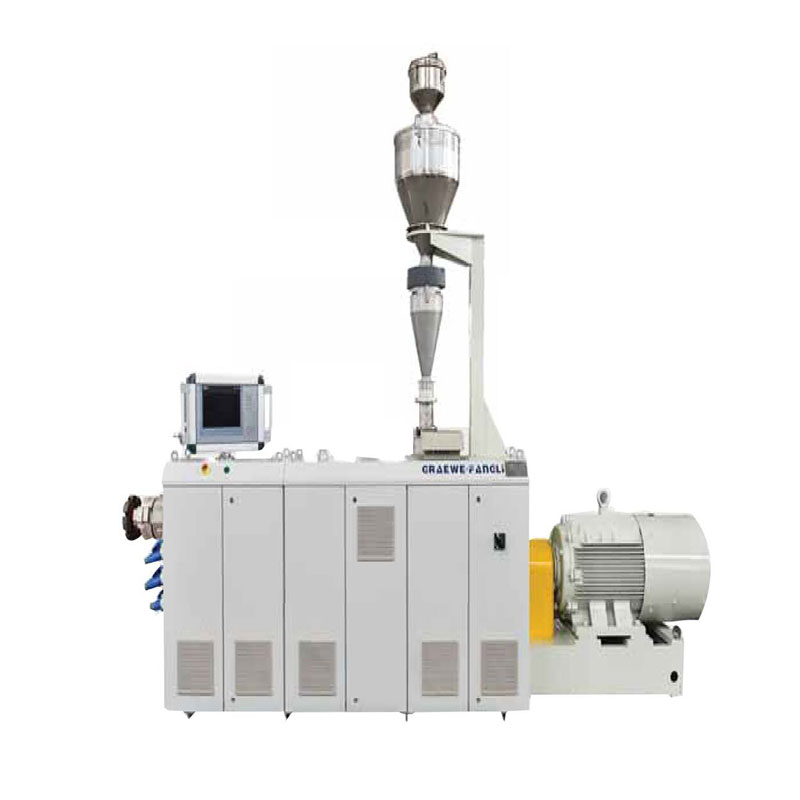

POK (Polyoxymethylene Ketone) pipe extrusion equipment—especially UL-certified systems—offers unique advantages due to the material's high-performance properties and the precision demands of regulated markets (such as electrical conduit, high-temperature plumbing, or fuel delivery). Below are the key advantages of POK pipe extrusion equipment built for UL standards:

✅ Advantages of POK Pipe Extrusion Equipment (UL Certified)

|

Advantage |

Explanation |

|

1. High-Temperature Stability |

POK processes at 240–270°C, requiring extrusion lines with high-temp zones, corrosion-resistant screws, and tight melt control. UL-certified systems ensure consistent wall thickness and thermal resistance. |

|

2. Excellent Dimensional Accuracy |

UL-certified equipment incorporates precision calibration sleeves, vacuum tanks, and laser diameter control, essential for tight tolerances in electrical or industrial POK applications. |

|

3. Chemical and Fuel Resistance Compatibility |

POK is often used for fuel lines or chemical fluid pipes—equipment must be built with high-alloy steel or bimetallic barrels to resist corrosion and abrasion. UL validation ensures long-term pipe integrity. |

|

4. Flame Retardancy and Compliance |

POK pipes for electrical conduits or transport must meet UL 94 V-0 and other flammability standards. UL-rated equipment ensures consistent extrusion quality to pass these tests. |

|

5. Integrated Cooling & Stress Relieving |

POK requires controlled cooling and post-extrusion stress relief. UL-certified lines often feature multi-stage water tanks or heating-cooling zones for annealing and dimensional stability |

|

6. Multi-Layer/Co-Extrusion Compatibility |

POK pipes can be co-extruded with protective outer layers (e.g., EVOH, flame-retardant). UL-grade lines often include co-extruder integration and multi-channel die-heads. |

|

7. Advanced Automation and Monitoring |

UL pipe extrusion lines use PLC + HMI control, with real-time thickness, ovality, and melt pressure monitoring. This ensures consistency for regulated pipe grades. |

|

8. End-Use Certification Support |

Machines designed for UL applications often come with supporting documentation, calibration logs, and data tracking for easier pipe batch traceability and UL audit readiness. |

Typical Applications of UL-Standard POK Pipes:

· Electrical conduit (UL 651 compliant)

· Fuel system pipes (automotive & aerospace)

· High-pressure chemical transport pipes

· Hot water or steam transport pipes

· Reinforced composite pipes (POK + glass/carbon fiber)

Ideal Line Configuration:

· High-torque single-screw extruder with corrosion-resistant metallurgy

· Melt pumps for precision dosing

· Stainless steel vacuum calibration & spray tanks

· Multi-caterpillar haul-off

· Chipless or planetary cutter

· Optional: In-line annealing tunnel or post-curing oven