- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Industry Knowledge

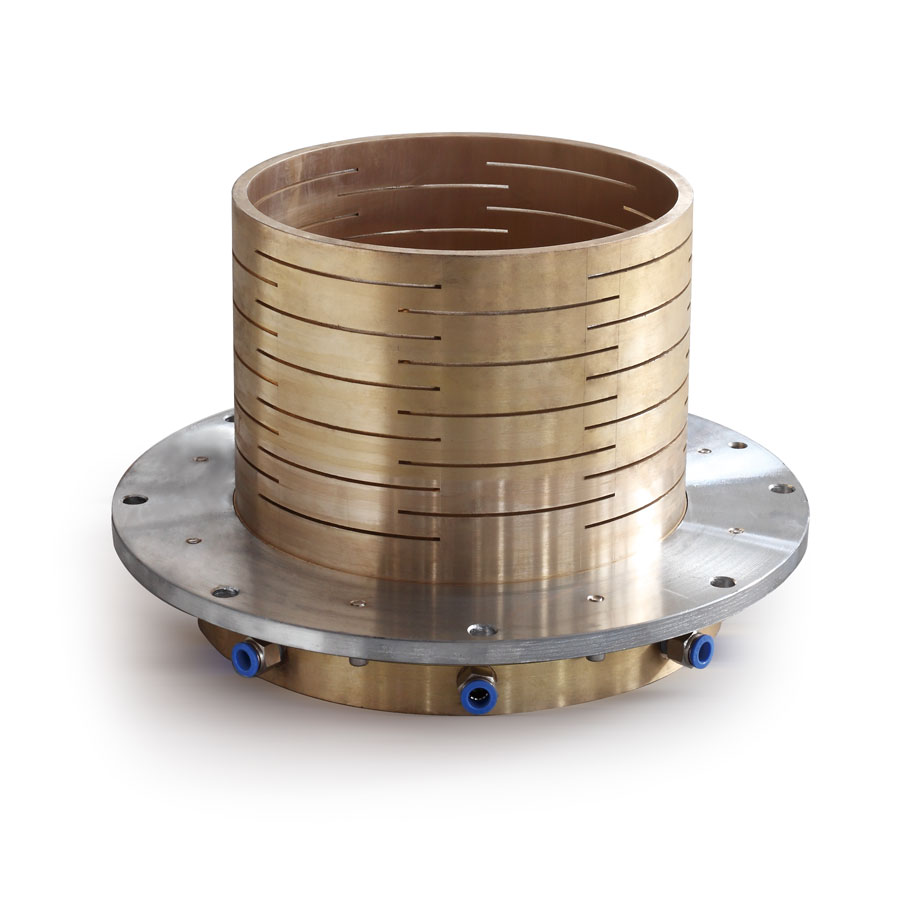

Application of spiral die head

Spiral die-heads are widely used in plastic extrusion, rubber processing, metal drawing and other fields. It is usually designed to ensure uniform heating, mixing and extrusion of materials during the production process. Here are some common uses of spiral die-heads: Plastic processing: In the plas......

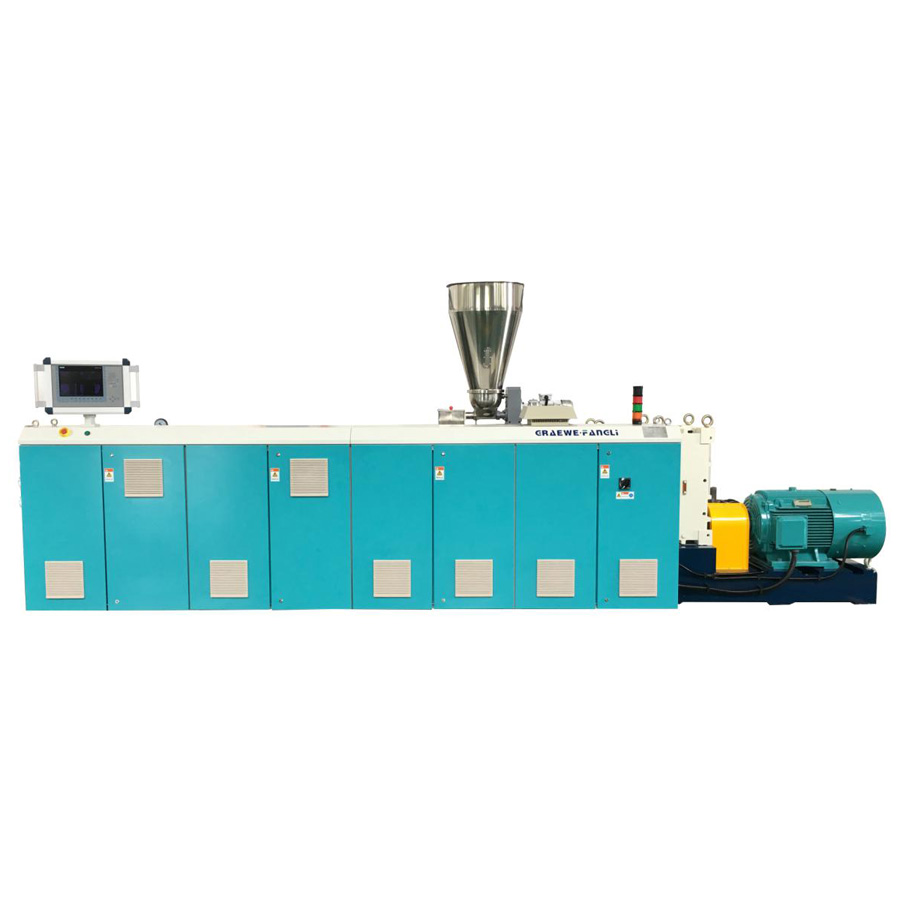

Read MoreHow to use Easy-maintainable pipe extruder

Using an Easy-Maintainable Pipe Extruder follows standard extrusion practices but includes design optimizations that simplify cleaning, part replacement, and routine servicing. Here's a step-by-step guide to both operating and maintaining it effectively:

Read MoreWhen to Choose a Bulk Spiral Die-head?

Choosing a Bulk Spiral Die-head is a strategic decision based on the type of pipe, output requirements, and quality expectations. Here's when you should choose a Bulk Spiral Die-head: ✅ When to Choose a Bulk Spiral Die-head 1. Producing Large-Diameter Pipes Ideal for HDPE/PE/PP pipes with diamete......

Read MoreWhat's the advantage of Durable Calibration Sleeve ?

A Durable Calibration Sleeve is a key component in plastic pipe extrusion, especially during vacuum calibration. Its main job is to shape and cool the pipe accurately as it exits the die. A durable calibration sleeve adds significant value in terms of performance, cost-efficiency, and consistency.

Read MoreWorking principle of counter-rotating parallel twin screw extruder

The counter-rotating parallel twin-screw extruder is a highly efficient plastic processing equipment, mainly used for the mixing, extrusion, plasticization and other processes of plastics. It consists of two parallel screws that rotate in opposite directions. Its working principle mainly includes th......

Read MoreWhat kind of customer use the corrugated pipe extruder UL?

Customers who use corrugated pipe extruders with UL certification are typically manufacturers or contractors operating in regulated markets where safety, quality, and compliance are essential. Here's a breakdown of the types of customers and why they require UL-certified equipment:

Read More